|

| August 03, 2021 | Volume 17 Issue 29 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Researchers work out how to optimize Army engines that use jet and other fuels

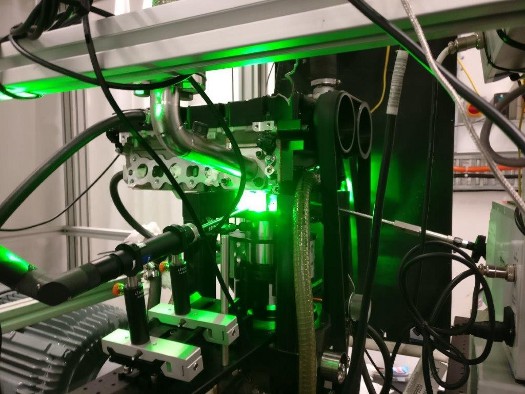

Engine testing setup. [Credit: U.S. Army]

A U.S. Army study has uncovered a new method that will optimize engine efficiency in future ground and unmanned aerial systems (UAS) platforms.

Researchers from the U.S. Army Combat Capabilities Development Command's (DEVCOM) Army Research Laboratory and the University of New South Wales (Sydney, Australia) discovered the precise dependence of ignition delay on temperatures at specific conditions in compression-ignition intermittent combustion engines using advanced laser diagnostics and a systematic, experimental approach.

Ignition delay is a critical parameter in compression-ignition engines, as it determines when combustion starts -- which significantly influences engine performance, efficiency, and reliability. In extreme operating conditions such as in UAS, the start of combustion can induce detonation or flameout. Detonation can damage the engine, while flameout can lead to crashes because the air vehicles lose thrust.

"Start-of-combustion timing is critical to both engine performance and reliability of the Army vehicles due to the unique operating environment and the use of military fuels called jet fuels," said Dr. Kenneth Kim, a scientist at ARL. "We assessed numerous methods reported in the previous studies by optically measuring start of combustion, and discovered that the actual start of combustion has excellent correlations with the gas temperature at the start of combustion and the temperature difference between the start of fuel injection and the start of combustion."

Accurate measurement of start of combustion has always been subjective and inaccurate, which makes designing the experimental boundary conditions challenging for researchers. This new discovery provides insights into design of combustion experiments and opportunities to control combustion precisely to improve engine performance and reliability.

Researchers said this advancement directly impacts the development of Army ground and air vehicles that use compression-ignition intermittent combustion engines.

In the future, this new discovery can improve accuracy of ignition delay calculations across different combustion experimental rigs used for a variety of types of engine experiments during development, Kim said.

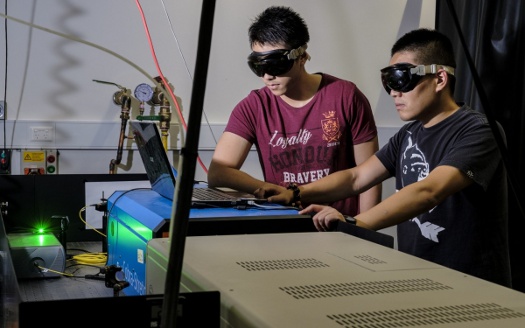

Army researchers identify a method for more efficient diesel engines. [Credit: U.S. Army]

With the accurate ignition delay results, researchers will be able to enhance performance, efficiency, and reliability using an improved engine calibration that can prevent both flame-out and detonation or develop a new engine with multi-fuel capability and precise prediction of ignition. This will result in reliable, more efficient, higher payload engines in various Army air and ground vehicles. These Army vehicles will be capable of operating for up to seven days using indigenous fuels without resupply, supporting Army Multi-Domain Operations.

The systematic laser diagnostics method proved that the pressure recovery point in an in-cylinder pressure profile is the closest to the actual start of combustion among numerous methods reported in the existing body of research. For this research, the team measured the precise start of combustion in an optically accessible engine affixed with a transparent quartz window, providing visibility to the actual combustion event in the engine while the optical measurement using lasers enabled further analysis of fuel breakdown and ignition and combustion processes.

Researchers can use these optical measurements to track certain chemical species, which can serve as markers to better understand ignition and combustion processes.

"Current Army systems are limited to use only jet fuels, but this research aims to enable the burning of any type of liquid fuel," Kim said. "This is part of the lab's Versatile Tactical Power and Propulsion Essential Research Program, which is working to develop component technologies that enable hybrid-electric multi-fuel capable propulsion systems."

The team works with other Army programs and researchers, such as the Center for UAS Propulsion, to share and apply this knowledge to current and future advances in UAS propulsion systems in the areas of reliability, payload, signatures, and range.

"International collaboration is crucial to the Army's efforts to have access to world-class research around the world, exchange ideas with leading subject matter experts in all fields, and maximize return on investment," said Dr. Sandy Young, a scientist at ARL. "This research collaboration with the University of New South Wales is an excellent example of this."

The researchers published their findings, "Assessments of Pressure-Based Ignition Delay Measurements of Various Cetane Number Fuels in a Small-Bore Compression Ignition Engine," in the peer-reviewed Society of Automotive Engineer International Journal of Engines.

Source: U.S. Army DEVCOM Army Research Laboratory

Published August 2021

Rate this article

View our terms of use and privacy policy